Ama-lens we-macro macroUbe ngomunye wamathuluzi asemqoka kwinqubo yokukhiqiza ngogesi ngenxa yokusebenza kwawo okuphezulu kokucabanga kanye namakhono okulinganisa aqondile. Kulesi sihloko, sizofunda ngezinhlelo ezithile zelensi yezimboni macro ekukhiqizweni kwe-elekthronikhi.

Izicelo ezikhethekile ze-Industrial Macro Lens ekukhiqizeni ngogesi

Isicelo 1: ukutholwa kwengxenye nokuhlunga

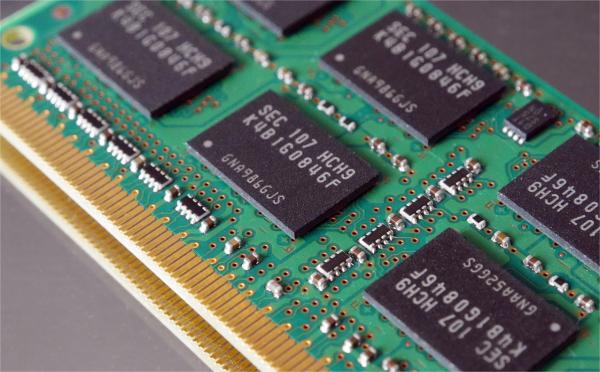

Enqubweni yokukhiqiza nge-elekthronikhi, izakhi ezahlukahlukene ze-elekthronikhi ezincane (ezifana nabamelana, ama-capacitors, ama-chip, njll.) Kudingeka ukuthi ahlolwe futhi ahlelwe.

Ama-lens we-macro macro anganikeza izithombe ezicacile ukusiza ukuthola iziciphici zokubona, ukunemba okunobukhulu nokuhleleka kwezinto ze-elekthronikhi, ngaleyo ndlela ziqinisekisa ikhwalithi nokuvumelana kwemikhiqizo.

Ukuhlolwa kwe-elektroniki nge-elekthronikhi

Isicelo 2: Ukulawulwa kwekhwalithi ye-Welding

I-Soldering yisinyathelo esibalulekile kwinqubo yokukhiqiza nge-elekthronikhi, futhi ikhwalithi yayo ithinta ngqo ukusebenza kanye nokwethenjwa komkhiqizo.

Ama-lens we-macro ezimboni angasetshenziswa ukuthola ubuqotho, ukujula kanye nokufana kwamajoyinti we-solder, kanye nokubheka iziphambeko zokuthengisa (njenge-spatter, imifantu, njll.), Ngaleyo ndlela zithola ukulawulwa okuqondile kanye nokuqapha kwekhwalithi yokuthengisa.

Isicelo 3: Ukuhlolwa kwekhwalithi ephezulu

Ikhwalithi yokubukeka yemikhiqizo ye-elekthronikhi ibalulekile esithombeni esiphelele kanye nokuncintisana kwemakethe kwemikhiqizo.

Ama-lens we-macro macroImvamisa isetshenziselwa ukuhlolwa kwekhwalithi ephezulu yemikhiqizo ukuthola iziphambeko, imihuzuko, amabala nezinye izinkinga ngaphezulu kwemikhiqizo ukuze kuqinisekiswe ukuphelela nokuvumelana kokubukeka komkhiqizo.

Isicelo 4: Ukuhlolwa kwe-PCB

I-PCB (I-Printred Circuit Board) ingenye yezingxenye ezibalulekile zemikhiqizo ye-elekthronikhi. Ama-lens we-macro macro asetshenziselwa ukuthola amajoyinti we-solder, izikhundla zezakhi nokuxhumeka kuma-PCB.

Ngokusebenzisa okuphezulu kanye nokucabanga okuphansi kokuhlanekezela, ama-lens we-macro aphansi angabona kahle izinkinga ezifana nekhwalithi ye-welding, isikhundla sengxenye yokuxhuma kanye nokuxhumana komugqa ukuze kuqinisekiswe ikhwalithi yomkhiqizo.

Ukuhlolwa kwekhwalithi ye-PCB

Isicelo 5: I-Assembly yedivayisi nokuma okuhle

Ehlelweni lomhlangano wemikhiqizo ye-elekthronikhi,Ama-lens we-macro macroIngasetshenziswa futhi ukuze ithole ngokunembile futhi ihlanganise izingxenye ezincane nezingxenye.

Ngokusebenzisa imisebenzi yesikhathi sangempela nemisebenzi yokulinganisa okuqondile, ama-lens wezimboni ama-macro angasiza abahlinzeki ngokunembile izingxenye ezindaweni eziqokiwe futhi baqinisekise ukuhlelwa kwabo okulungile nokuxhumana.

Imicabango yokugcina:

Ngokusebenza nabasebenza ngochwepheshe eChuangan, bobabili abaklami nezokwakha baphathwe ngonjiniyela abanamakhono kakhulu. Njengengxenye yenqubo yokuthenga, ummeleli wenkampani angachaza imininingwane eminingi eqondile ngohlobo lwelensi ofisa ukuyithenga. Uchungechunge lukaChuangan lwelensi imikhiqizo lusetshenziselwa izinhlelo eziningi zezicelo, kusukela ekubhekeni, ukuskena, ama-drones, izimoto kuya ezinhlotsheni ezihlukile zamalensi aqediwe, angashintshwa futhi asetshenziswe ngokwezidingo zakho. Xhumana nathi ngokushesha okukhulu.

Isikhathi Sokuthumela: Oct-08-2024