Lilense tsa macro tsa indasterie fetohile e 'ngoe ea lisebelisoa tsa bohlokoa haholo ts'ebetsong ea tlhahiso ea lisebelisoa tsa elektroniki ka lebaka la ts'ebetso ea tsona e phahameng ea ho nka litšoantšo le bokhoni bo nepahetseng ba ho lekanya. Sehloohong sena, re tla ithuta ka lits'ebeliso tse ikhethileng tsa lilense tsa macro tsa indasteri tlhahisong ea lisebelisoa tsa elektroniki.

Litšebeliso tse ikhethileng tsa lilense tsa macro tsa indasteri tlhahisong ea lisebelisoa tsa elektroniki

Kopo ea 1: Ho lemoha le ho hlopha likarolo

Mokgweng wa tlhahiso ya elektroniki, dikarolo tse nyane tse fapaneng tsa elektroniki (tse kang di-resistor, di-capacitor, di-chip, jj.) di hloka ho hlahlojwa le ho hlophiswa.

Lilense tsa macro tsa indasteri li ka fana ka litšoantšo tse hlakileng ho thusa ho lemoha liphoso tsa ponahalo, ho nepahala ha litekanyo le sebaka sa tlhophiso ea likarolo tsa elektroniki, ka hona ho netefatsa boleng le botsitso ba lihlahisoa.

Tlhahlobo ea likarolo tsa elektroniki

Kopo ea 2: Taolo ea boleng ba ho tjheseletsa

Ho kopanya thepa ke mohato oa bohlokoa ts'ebetsong ea tlhahiso ea elektroniki, 'me boleng ba eona bo ama ka kotloloho ts'ebetso le ts'epo ea sehlahisoa.

Lilense tse kholo tsa indasteri li ka sebelisoa ho lemoha botšepehi, botebo le ho tšoana ha manonyeletso a solder, hammoho le ho hlahloba liphoso tsa ho solder (tse kang ho fafatsa, mapetso, jj.), ka hona ho fihlella taolo le tlhokomelo e nepahetseng ea boleng ba ho solder.

Kopo ea 3: Tlhahlobo ea boleng ba bokaholimo

Boleng ba ponahalo ea lihlahisoa tsa elektroniki bo bohlokoa bakeng sa setšoantšo ka kakaretso le tlholisano 'marakeng ea lihlahisoa.

Lilense tsa macro tsa indasterihangata li sebelisoa bakeng sa tlhahlobo ea boleng ba bokaholimo ba lihlahisoa ho lemoha liphoso, mengoapo, matheba le mathata a mang holim'a lihlahisoa ho netefatsa phetheho le botsitso ba ponahalo ea sehlahisoa.

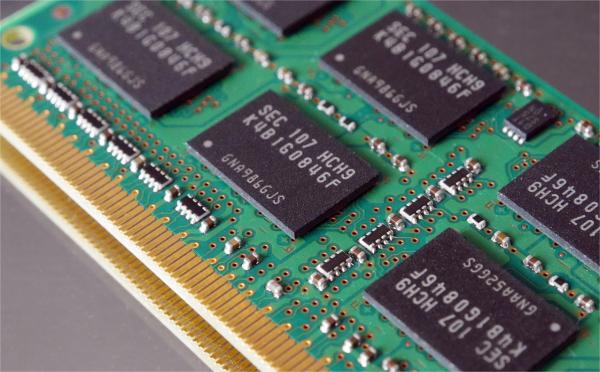

Kopo ea 4: Tlhahlobo ea PCB

PCB (Printed Circuit Board) ke e 'ngoe ea likarolo tsa mantlha tsa lihlahisoa tsa elektroniki. Lilense tsa macro tsa indasteri li ka sebelisoa ho lemoha manonyeletso a solder, maemo a likarolo le likhokahano ho li-PCB.

Ka ho nka litšoantšo tse nang le qeto e phahameng le tse sothehileng, lilense tsa macro tsa indasteri li ka lemoha mathata a kang boleng ba ho tjheseletsa, ho fokotsa boemo ba likarolo le khokahano ea mola ho netefatsa boleng ba sehlahisoa.

Tlhahlobo ea boleng ba PCB

Kopo ea 5: Kopano ea sesebelisoa le sebaka sa sona

Ts'ebetsong ea ho kopanya lihlahisoa tsa elektroniki,lilense tsa macro tsa indasterie ka boela ea sebelisoa ho fumana le ho kopanya likarolo le likarolo tse nyane ka nepo.

Ka ho nka litšoantšo ka nako ea sebele le mesebetsi e nepahetseng ea ho lekanya, lilense tsa macro tsa indasteri li ka thusa basebetsi ho beha likarolo ka nepo libakeng tse khethiloeng le ho netefatsa tlhophiso le khokahano ea tsona e nepahetseng.

Mehopolo ea ho Qetela:

Ka ho sebetsa le litsebi tsa ChuangAn, moralo le tlhahiso li sebetsoa ke baenjiniere ba nang le boiphihlelo bo phahameng. E le karolo ea ts'ebetso ea ho reka, moemeli oa k'hamphani a ka hlalosa ka botlalo tlhahisoleseling e tobileng mabapi le mofuta oa lense eo u batlang ho e reka. Letoto la lihlahisoa tsa lense tsa ChuangAn li sebelisoa lits'ebetsong tse fapaneng, ho tloha ho lekola, ho skena, li-drone, likoloi ho ea matlong a bohlale, jj. ChuangAn e na le mefuta e fapaneng ea lilense tse felileng, tse ka fetoloang kapa tsa fetoloa ho latela litlhoko tsa hau. Ikopanye le rona kapele kamoo ho ka khonehang.

Nako ea poso: Mphalane-08-2024