Industrial macro lenses have become one of the indispensable tools in the electronics manufacturing process due to their superior imaging performance and precise measurement capabilities. In this article, we will learn about the specific applications of industrial macro lenses in electronics manufacturing.

Specific applications of industrial macro lenses in electronics manufacturing

Application 1: Component detection and sorting

In the electronic manufacturing process, various tiny electronic components (such as resistors, capacitors, chips, etc.) need to be inspected and sorted.

Industrial macro lenses can provide clear images to help detect the appearance defects, dimensional accuracy and arrangement position of electronic components, thereby ensuring the quality and consistency of products.

Electronic component inspection

Application 2: Welding quality control

Soldering is an important step in the electronic manufacturing process, and its quality directly affects the performance and reliability of the product.

Industrial macro lenses can be used to detect the integrity, depth and uniformity of solder joints, as well as to check for soldering defects (such as spatter, cracks, etc.), thereby achieving precise control and monitoring of soldering quality.

Application 3: Surface quality inspection

The appearance quality of electronic products is crucial to the overall image and market competitiveness of the products.

Industrial macro lenses are often used for surface quality inspection of products to detect defects, scratches, stains and other problems on the surface of products to ensure the perfection and consistency of product appearance.

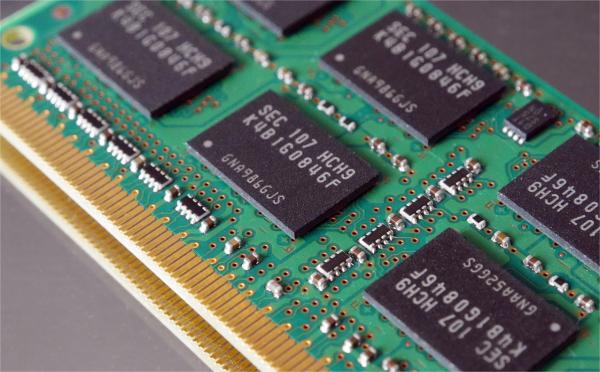

Application 4: PCB inspection

PCB (Printed Circuit Board) is one of the core components of electronic products. Industrial macro lenses can be used to detect solder joints, component positions and connections on PCBs.

Through high-resolution and low-distortion imaging, industrial macro lenses can accurately detect problems such as welding quality, component position offset and line connection to ensure product quality.

PCB quality inspection

Application 5: Device assembly and positioning

In the assembly process of electronic products, industrial macro lenses can also be used to accurately locate and assemble tiny components and parts.

Through real-time imaging and precise measurement functions, industrial macro lenses can help operators accurately place components in designated locations and ensure their correct arrangement and connection.

Final Thoughts:

By working with professionals at ChuangAn, both design and manufacturing are handled by highly skilled engineers. As part of the purchasing process, a company representative can explain in more detail specific information about the type of lens you wish to purchase. ChuangAn’s series of lens products are used in a wide range of applications, from surveillance, scanning, drones, cars to smart homes, etc. ChuangAn has various types of finished lenses, which can also be modified or customized according to your needs. Contact us as soon as possible.

Post time: Oct-08-2024