Industrial lenses are widely used. In addition to their applications in industrial inspection, security monitoring, 3C electronics and other industries, they are also widely used in the PCB (Printed Circuit Board) industry.

Specific application directions of industrial lenses in the PCB industry

The specific application of industrial lenses in the PCB industry can be summarized into the following main directions:

1.Automated production

Industrial lenses combined with machine vision systems can be used in automated equipment on PCB production lines, such as automatic welding robots, placement machines, etc., to achieve automated detection, positioning and processing on PCB production lines.

Industrial lenses can provide high-definition images, enabling the robot system to accurately and quickly identify and process information such as the location of PCB boards and component layout, thereby achieving an efficient automated production process.

2.Testing and quality control

In the PCB industry, industrial lenses are widely used to detect and inspect the quality and integrity of PCB boards. Through the high resolution and clarity of optical lenses, the quality of solder joints, component positions, defects and flaws on PCBs can be detected to ensure product quality and reliability.

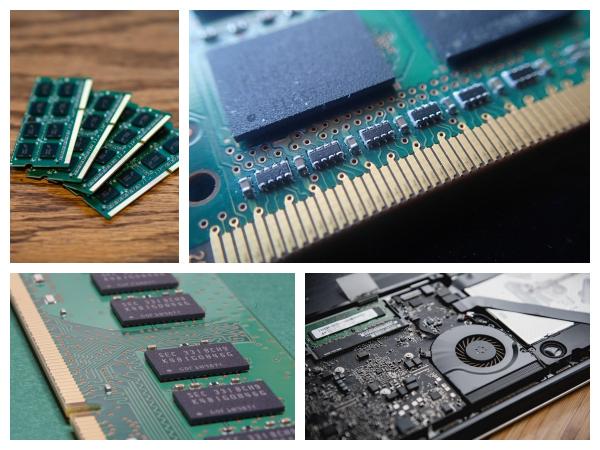

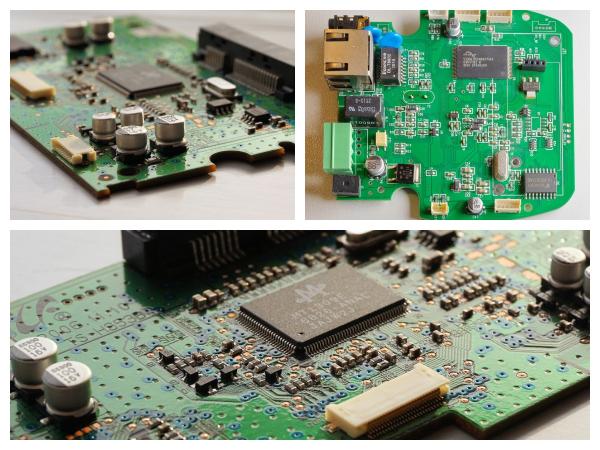

Industrial lenses are applied to PCB industry

3.Precise positioning and measurement

In the production process of the PCB industry, industrial lenses can be used to accurately locate components and connection points on the PCB, and to measure and verify them to ensure the accuracy and precision of component installation and connection.

For example, in processes such as PCB drilling and gold finger welding, the position needs to be precisely controlled. Industrial lenses can provide clear and accurate images to help achieve precise positioning and processing, ensuring processing quality.

4.Surface inspection

The quality of the PCB surface is crucial to product performance. Industrial lenses can be used for surface inspection to check whether the PCB surface is flat, scratch-free, flawless, etc.

Through high-precision optical imaging, industrial lenses can detect tiny surface defects and problems, and handle and repair them in a timely manner to ensure product quality.

Industrial lenses are used in PCB quality inspection

5.Imaging analysis

Industrial lenses can provide high-resolution imaging capabilities for microscopic observation and analysis of tiny components, lines and solder joints on PCBs, helping to identify potential problems for precise design and production.

In addition, industrial lenses can also be combined with image processing systems for data collection and analysis. Images taken by industrial lenses can be used for data extraction, analysis and storage to help optimize production processes, improve efficiency and quality control.

Final Thoughts:

ChuangAn has carried out the preliminary design and production of industrial lenses, which are used in all aspects of industrial applications. If you are interested in or have needs for industrial lenses, please contact us as soon as possible.

Post time: Mar-04-2025