In order to ensure that the lens can provide high-quality images and reliable performance in specific application scenarios, it is necessary to conduct relevant evaluations on the lens. So, what are the evaluation methods for machine vision lenses? In this article, we will learn how to evaluate machine vision lenses.

How to evaluate machine vision lenses

What are the evaluation methods for machine vision lenses?

The evaluation of machine vision lenses needs to consider many aspects of performance parameters and characteristics, and needs to be carried out under the operation of specialized equipment and professionals to ensure that the evaluation results are correct and effective.

The following are the main evaluation methods:

1.Field of view test

The field of view of a lens determines the size of the scene that the optical system can see, and can usually be evaluated by measuring the diameter of the image formed by the lens at a specific focal length.

2.Distortion test

Distortion refers to the deformation that occurs when a lens projects a real object onto the imaging plane. There are two main types: barrel distortion and pincushion distortion.

Evaluation can be done by taking calibration images and then performing geometric correction and distortion analysis. You can also use a standard resolution test card, such as a test card with a standard grid, to check whether the lines on the edges are curved.

3.Resolution test

The resolution of the lens determines the detail clarity of the image. Therefore, resolution is the most critical test parameter of the lens. It is usually tested using a standard resolution test card with corresponding analysis software. Usually, the resolution of the lens is affected by factors such as aperture size and focal length.

Lens resolution is affected by many factors

4.Back focal length test

Back focal length is the distance from the image plane to the back of the lens. For a fixed focal length lens, the back focal length is fixed, while for a zoom lens, the back focal length changes as the focal length changes.

5.Sensitivity test

Sensitivity can be evaluated by measuring the maximum output signal that a lens can produce under specific lighting conditions.

6.Chromatic aberration test

Chromatic aberration refers to the problem caused by the inconsistency of the focus points of various colors of light when the lens forms an image. Chromatic aberration can be evaluated by observing whether the color edges in the image are clear, or by using a special color test chart.

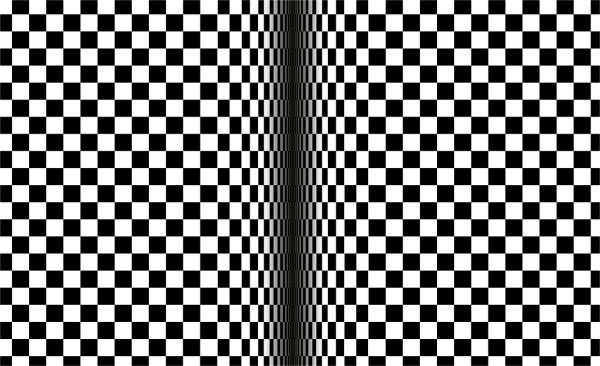

7.Contrast test

Contrast is the difference in brightness between the brightest and darkest points in the image produced by a lens. It can be assessed by comparing a white patch to a black patch or by using a special contrast test chart (such as a Stupel chart).

Contrast test

8.Vignetting test

Vignetting is the phenomenon that the brightness of the edge of the image is lower than that of the center due to the limitation of the lens structure. Vignetting test is usually measured using a uniform white background to compare the brightness difference between the center and edge of the image.

9.Anti-Fresnel reflection test

Fresnel reflection refers to the phenomenon of partial reflection of light when it propagates between different media. Usually, a light source is used to illuminate the lens and observe the reflection to evaluate the anti-reflection ability of the lens.

10.Transmittance test

Transmittance, that is, the transmittance of the lens to fluorescence, can be measured using equipment such as a spectrophotometer.

Final Thoughts:

ChuangAn has carried out the preliminary design and production of machine vision lenses, which are used in all aspects of machine vision systems. If you are interested in or have needs for machine vision lenses, please contact us as soon as possible.

Post time: Sep-10-2024