Types of industrial lens mount

There are mainly four types of interface, namely F-mount, C-mount, CS-mount and M12 mount. The F-mount is a general-purpose interface, and is generally suitable for lenses with a focal length longer than 25mm. When the focal length of the objective lens is less than about 25mm, due to the small size of the objective lens, the C-mount or CS-mount is used, and some use the M12 interface.

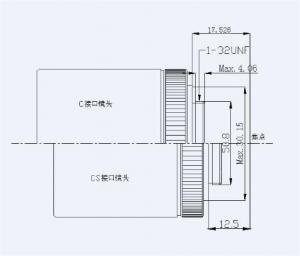

The difference between C mount and CS mount

The difference between C and CS interfaces is that the distance from the contact surface of the lens and the camera to the focal plane of the lens (the position where the CCD photoelectric sensor of the camera should be) is different. The distance for the C-mount interface is 17.53mm.

A 5mm C/CS adapter ring can be added to a CS-mount lens, so that it can be used with C-type cameras.

The difference between C mount and CS mount

Basic parameters of industrial lenses

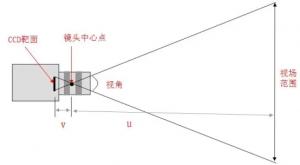

Field of view (FOV):

FOV refers to the visible range of the observed object, that is, the part of the object captured by the camera’s sensor. (The range of the field of view is something that must be understood in the selection)

Field of view

Working Distance (WD):

Refers to the distance from the front of the lens to the object under test. That is, the surface distance for clear imaging.

Resolution:

The smallest distinguishable feature size on the inspected object that can be measured by the imaging system. In most cases, the smaller the field of view, the better the resolution.

Depth of view (DOF):

The ability of a lens to maintain the desired resolution when objects are closer or farther from the best focus.

Depth of view

Other parameters of industrial lenses

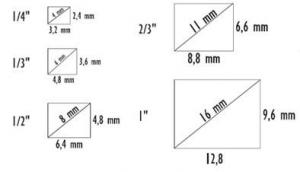

Photosensitive chip size:

The effective area size of the camera sensor chip, generally refers to the horizontal size. This parameter is very important to determine the proper lens scaling to obtain the desired field of view. The lens primary magnification ratio (PMAG) is defined by the ratio of the size of the sensor chip to the field of view. Although the basic parameters include the size and field of view of the photosensitive chip, PMAG is not a basic parameter.

Photosensitive chip size

Focal length (f):

“Focal length is a measure of the concentration or divergence of light in an optical system, which refers to the distance from the optical center of the lens to the focus of light gathering. It is also the distance from the center of the lens to the imaging plane such as the film or CCD in a camera. f={working distance/field of view long side (or short side)}XCCD long side (or short side)

The influence of the focal length: the smaller the focal length, the greater the depth of field; the smaller the focal length, the greater the distortion; the smaller the focal length, the more serious the vignetting phenomenon, which reduces the illumination at the edge of the aberration.

Resolution:

Indicates the minimum distance between 2 points that can be seen by a set of objective lenses

0.61x used wavelength (λ) / NA = resolution (μ)

The above calculation method can theoretically calculate the resolution, but does not include distortion.

※The wavelength used is 550nm

Defination:

The number of black and white lines can be seen in the middle of 1mm. Unit (lp)/mm.

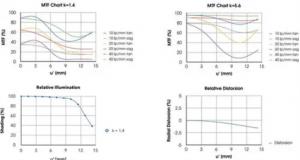

MTF(Modulation Transfer Function)

MTF

Distortion:

One of the indicators to measure the performance of the lens is aberration. It refers to the straight line outside the main axis in the plane of the subject, which becomes a curve after being imaged by the optical system. The imaging error of this optical system is called distortion. Distortion aberrations only affect the geometry of the image, not the sharpness of the image.

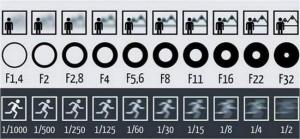

Aperture and F-Number:

A lenticular sheet is a device used to control the amount of light passing through a lens, usually inside the lens. We use the F value to express the aperture size, such as f1.4, F2.0, F2.8, etc.

Aperture and F-Number

Optical magnification:

The formula used to calculate the main scaling ratio is as follows: PMAG = sensor size (mm) / field of view (mm)

Display magnification

Display magnification is widely used in microscopy. The display magnification of the measured object depends on three factors: the optical magnification of the lens, the size of the sensor chip of the industrial camera (the size of the target surface), and the size of the display.

Display magnification = lens optical magnification × display size × 25.4 / rake diagonal size

Main categories of industrial lenses

Classification

•By focal length: prime and zoom

•By aperture: fixed aperture and variable aperture

•By interface: C interface, CS interface, F interface, etc.

•Divided by multiples: fixed magnification lens, continuous zoom lens

•The very important lenses commonly used in the machine vision industry mainly include FA lenses, telecentric lenses and industrial microscopes, etc.

The main points that must take into account in choosing a machine vision lens:

1. Field of view, optical magnification and desired working distance: When choosing a lens, we will choose a lens with a slightly larger field of view than the object to be measured, in order to facilitate motion control.

2. Depth of field requirements: For projects that require depth of field, use a small aperture as much as possible; when selecting a lens with a magnification, choose a lens with a low magnification as far as the project permits. If the project requirements are more demanding, I tend to choose a cutting-edge lens with a high depth of field.

3. Sensor size and camera interface: For example, the 2/3″ lens supports the largest industrial camera rake surface is 2/3″, it cannot support industrial cameras larger than 1 inch.

4. Available space: It is unrealistic for customers to change the size of the equipment when the scheme is optional.

Post time: Nov-15-2022